What we do

Verify. Decide. Deliver

We help industrial organizations make capital and execution decisions grounded in operational reality, not assumptions.

In practice, this means:

Verifying how operations truly perform.

Defining what can realistically be improved, and what cannot.

Delivering results through execution or validated CAPEX decisions, depending on what the reality requires.

Why Performance Fails

The Execution Gap

Most industrial underperformance is not driven by strategy or technology, but by execution gaps between financial plans and shop-floor reality.

Structural Root Causes:

Capital decisions taken without operational ground truth.

Performance hidden behind aggregated dashboards.

Value erosion during implementation and scale-up.

The consequence: value destruction hidden behind seemingly solid financial plans.

Once the problem is clear, execution becomes a choice

— not a gamble.

Three Decision Gates. One Logic

Every capital or execution decision fails when one of these questions remains unanswered.

Should we invest, fix or exit?

Ground-truth performance before capital is committed.

How do we turn strategy into execution?

From intent to shop-floor results, without value leakage.

Is CAPEX really justified?

Benchmarking reality, not vendor promises.

Low-Risk Entry Points

Our modular approach is designed to validate fit, build trust, and test potential before deeper engagement.

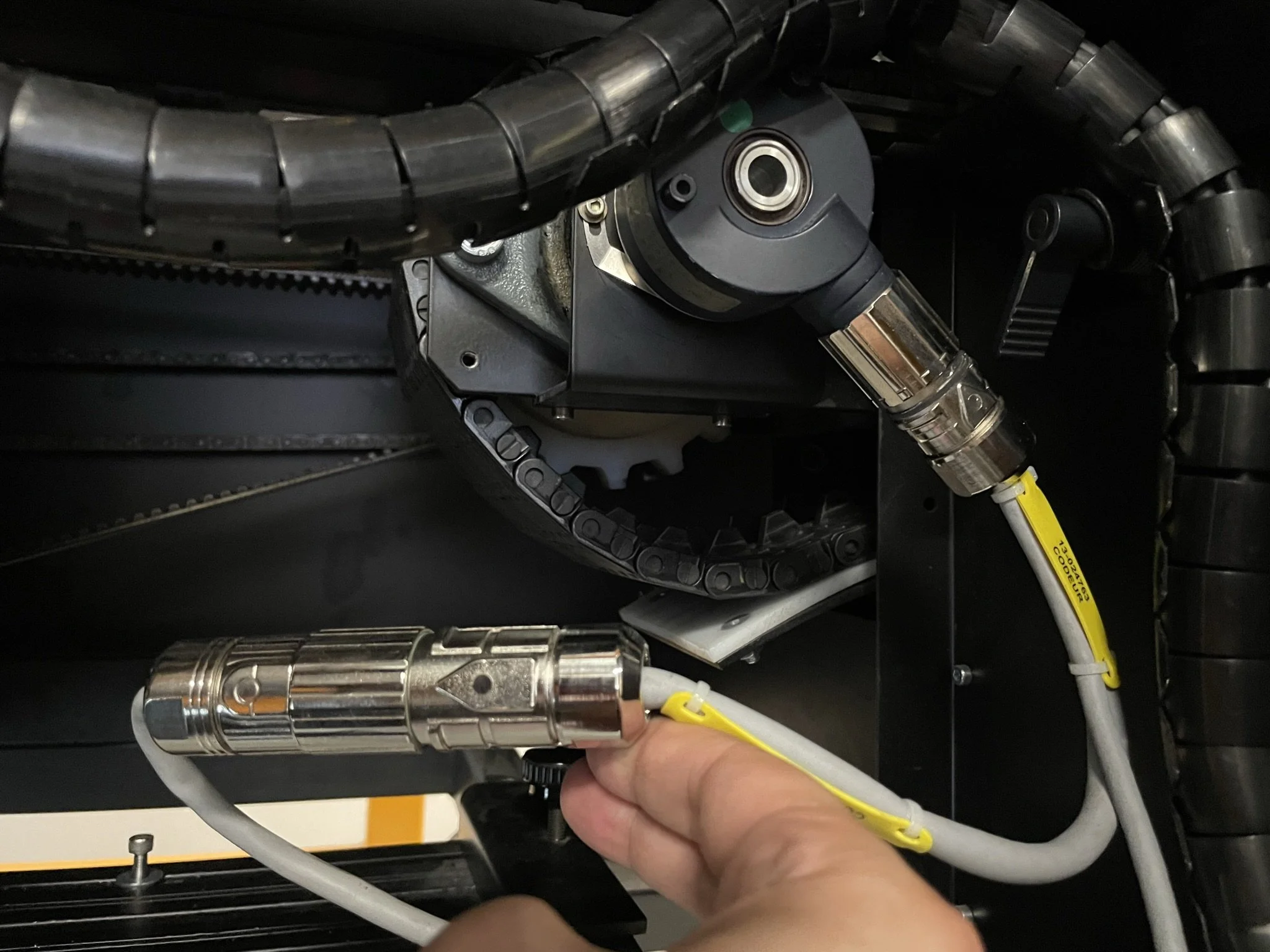

Short, on-site interventions to implement and test specific improvements on the shop floor and measure real operational and economic impact before scaling.

Audits — Performance Audit

Training — Lean Capability

Short, data-driven workshops using real plant data to build execution capability and validate whether teams can realistically deliver improvements.

Workshops — Execution Sprints

A rapid, scoped assessment to quantify real operational losses, uncover execution gaps, and validate whether an opportunity is worth deeper analysis.

Why Saikaris

Our guarantee

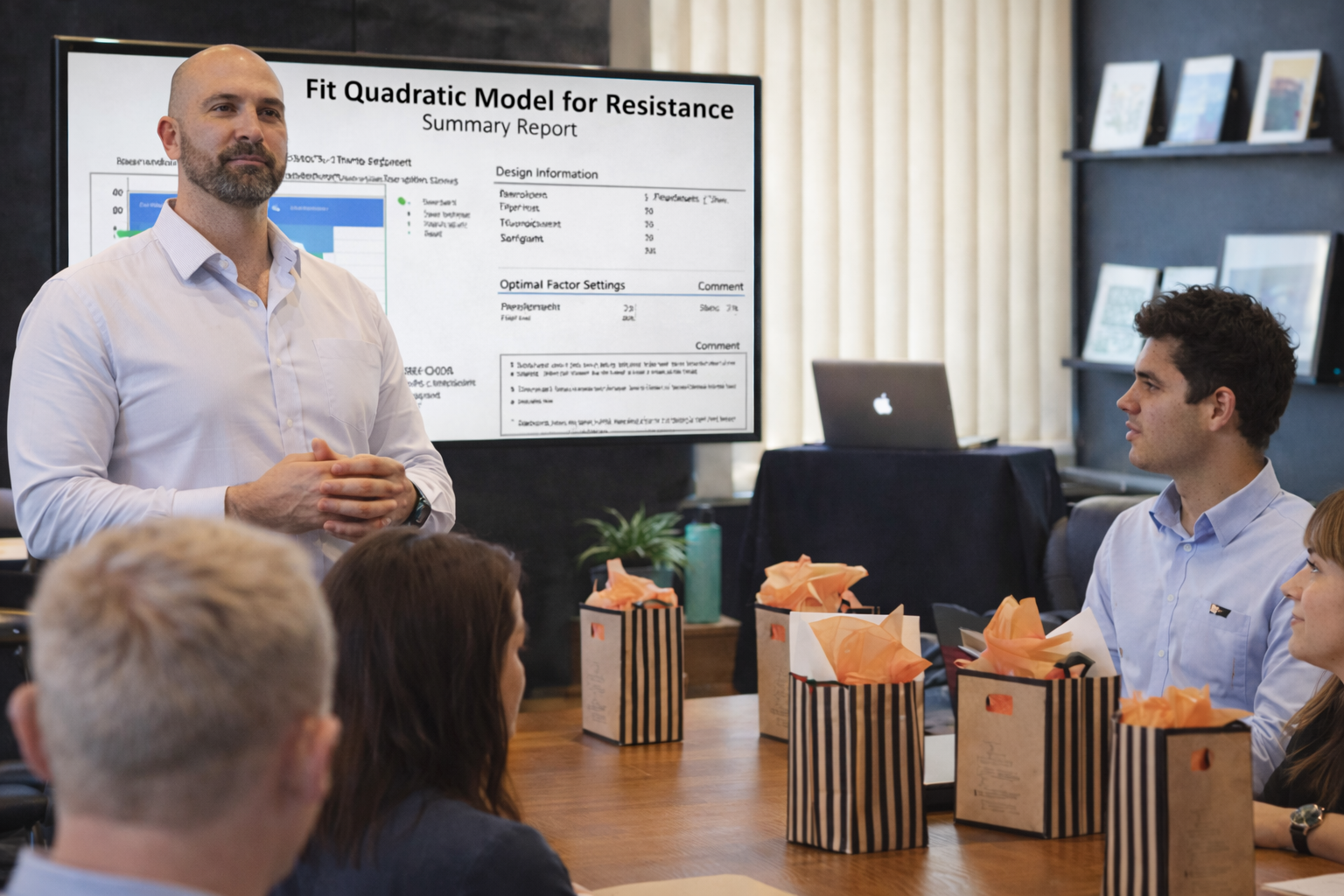

Lean Six Sigma Black Belt discipline

10+ countries frontline delivery

Training systems & standardization

AI validation & deployment experience

“We align our incentives with yours. If we don’t identify measurable value within the agreed scope, our fees are capped at expenses.”

Case Studies

Proven impact in the field

Premium Spirits Production:

€85k annual gross profit upside.

170k sellable bottles recovered per production line per year.

Operational Stability & Labor Efficiency:

€40k annual COGS released

Achieved through a 70% reduction in inspection complexity lowering manual intervention, especially across night shifts.

High-Volume Beer Production:

€70k annual gross profit upside:

715k sellable bottles recovered per production line per year

14% reduction in customer complaint exposure

Thanks to automation and defect assimilation programs.

Critical Operational Turnaround:

€1M revenue protected and secured under critical operational risk.

Operational turnaround reversed contract cancellation and restored customer confidence.